CNC Milling Centers

Snyder Industries’ milling department consists of several OKK and Mazak milling machines. With designated fixtures, they are able to run parts vertically and horizontally. Each of our mills have Fanuc CNC controls.

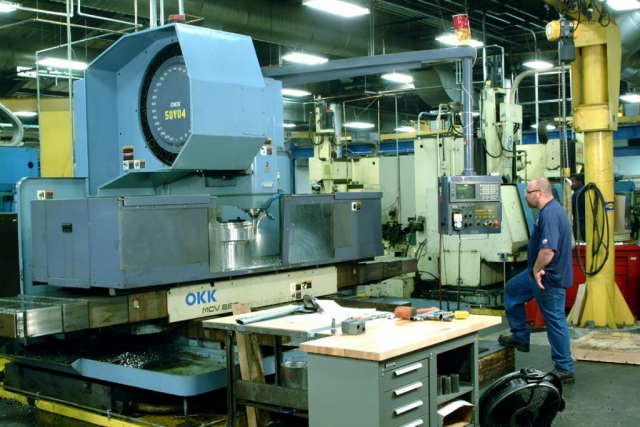

OKK Mills

OKK Milling centers at Snyder can hold parts as large as 77” OD, 59” OAL, and 11,000 lbs. Each of our seven (7) horizontal mills are equipped with a pallet system and operated with Fanuc CNC controls. Snyder has machine helpers that can assist with set ups on these pallet machines.

Five (5) vertical and seven (7) horizontal OKK mills are able to run complex features. The operator can hold finished dimensions to tolerances of .0002” on size and location.

Mazak Mills

Snyder’s Mazak mills are equipped with Paletech loading systems, which allows the operator to focus on keeping the machine running throughout the day. The two H-800X machines are fed by a 16-pallet loading track.

The Mazak Ultra-650 has designated tombstones and other fixtures that are used to reduce setup times on its loading system.

Each Mazak mill has their own 120 or 160 capacity tool carousel and automatic tool changers pre-loaded for different jobs or to provide backup tools as needed.

Gun Drill

Snyder Industries has the ability to deep hole drill up to 60” depth using a Tarus gun drill milling machine.

Snyder Industries’ milling department can satisfy most of your machining needs, from large amounts of stock removal to holding a tight tolerance bore location.

Get A CNC Milling Quote

We would be happy to provide your company with a quote on the part you need. To get started now go to our online quote form.